Guide to Finding Injection Molding Partners in China

The important meeting has recently finished, your new product is a go, time is pressing, and funding is, to put it mildly, limited. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. It seems sensible at first glance. The potential savings can be massive. Yet your thoughts are already spinning. You know the rumors, don’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Sourcing plastic mold doesn’t have to be a gamble. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This becomes the bedrock of your sourcing project.

What should you include?

First, your 3D CAD files. These are non-negotiable. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Think tolerances, material grades, finish specs, and any feature-critical notes. Any seal surfaces or critical hole sizes must be clearly labeled.

After that, material choice. Avoid generic terms like “Plastic.” Nor just “ABS.” Be specific. If you need SABIC Cycolac MG38 in black, say exactly that. Why be exact? Because resin grades number in the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

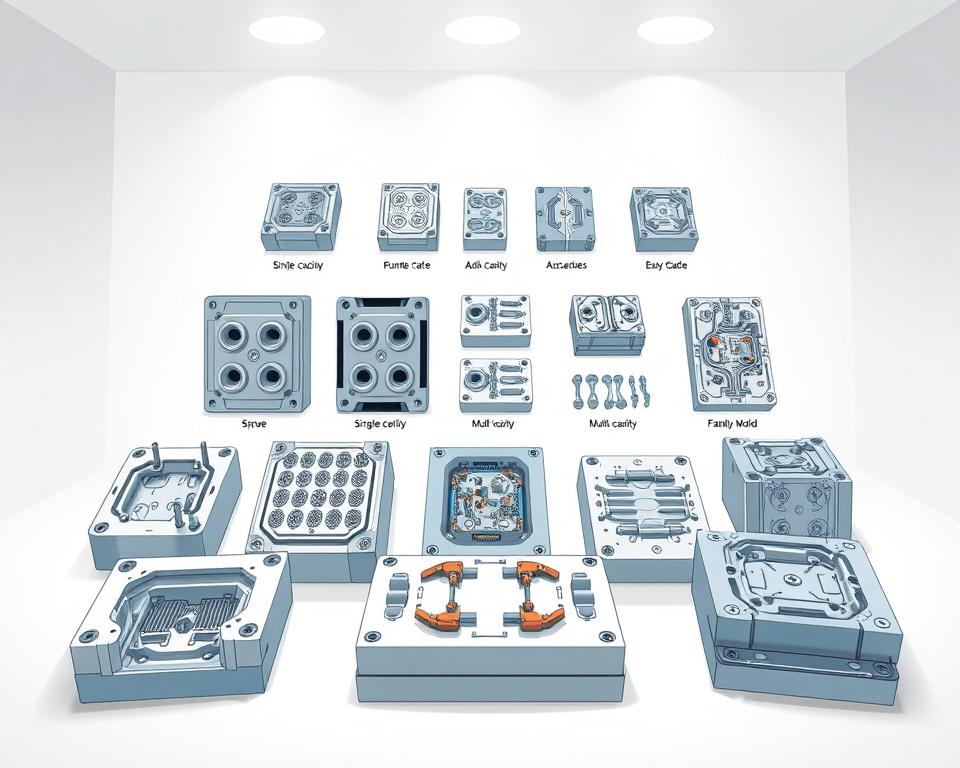

Finally, include the business details. What’s your forecasted annual volume (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

Okay, your RFQ package is a work of art. who gets your RFQ? Online sourcing is global but crowded. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Treat them as initial research tools, not final solutions. Narrow your pool to about a dozen promising firms.

However, don’t end your search there. Consider using a sourcing agent. True, they charge a fee. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Tap your professional contacts. Peer endorsements carry huge weight.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It blends technical checks with intuition.

Step one: audit communication. Do they respond quickly and clearly? Do they communicate effectively in English? But the key: do they probe your RFQ? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. It proves their expertise and involvement. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Ask for a list of their equipment. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Finally, inspect the factory. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the process kicks off.

Initially, expect a DFM report. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. You iterate with their team to optimize the mold.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are the very first parts off the new tool. They are your moment of truth.

Expect T1s to need tweaks. It’s par for the course. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold samples. You may repeat this cycle a few times. Build buffer time for sample iterations.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This is your golden sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Now comes full-scale production. How do you maintain consistency for part 10,000?

You need a clear Quality Control plan. Typically, this means a pre-shipment audit. Use a third-party inspector again. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Understand the shipping terms, or Incoterms. Does FOB apply, passing risk at the ship’s rail? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It relies on partnership-building. View them as allies, not vendors. Transparent dialogue, respect, and process discipline win. Certainly, it’s complex. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.